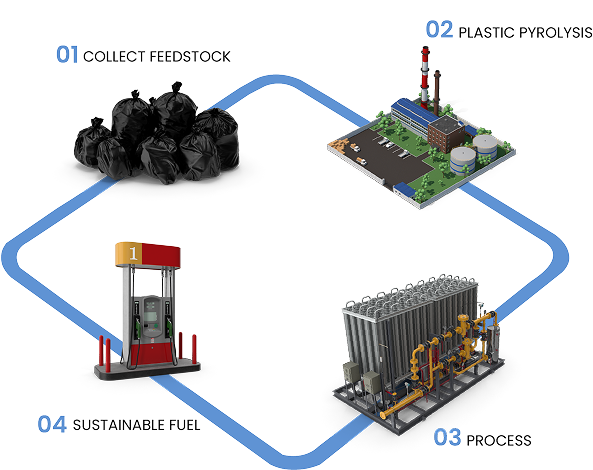

Our Process

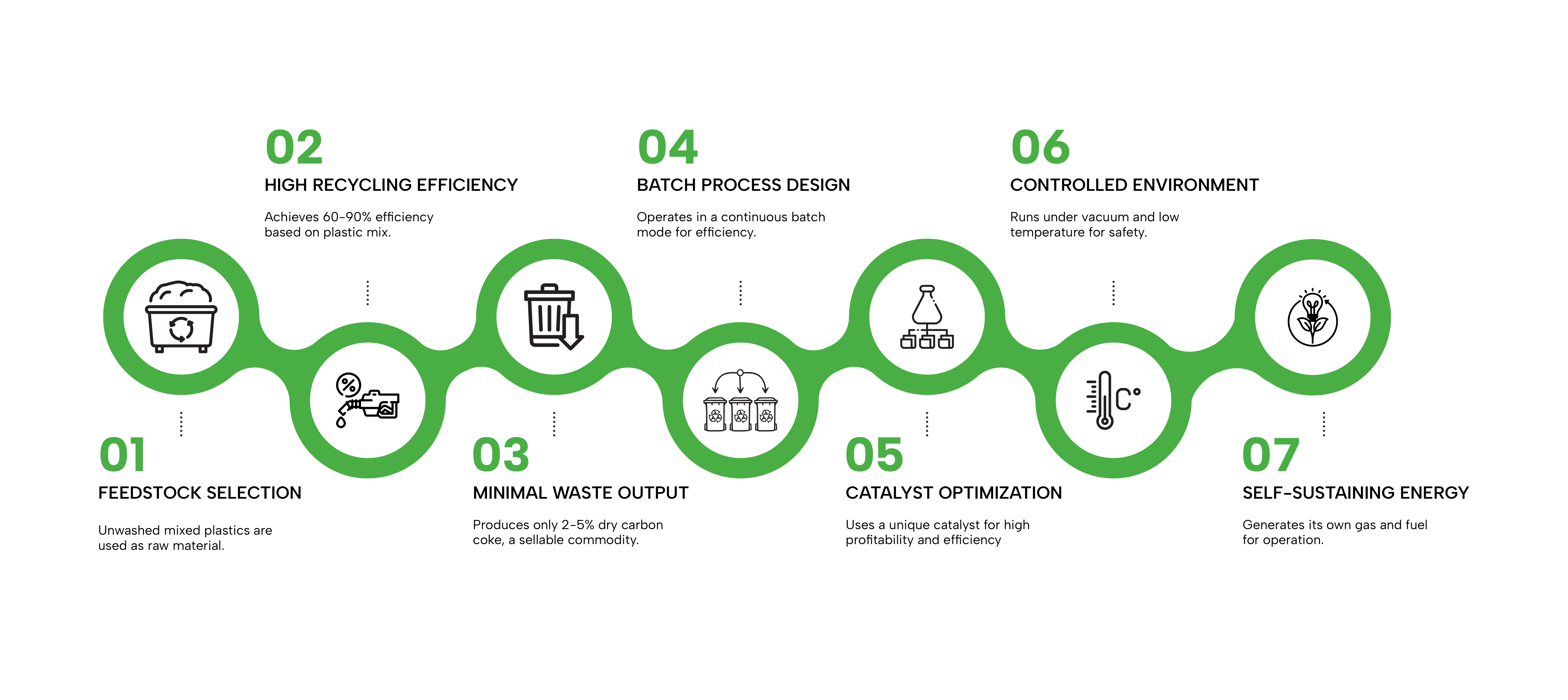

Our ProcessSince 2011, Sahasra Enviro has been specializing in the processing of non-recyclable plastics. We use advanced pyrolysis technology to convert waste plastics into valuable products like fuel, while ensuring energy self-sufficiency and sustainability throughout the process

These dedicated efforts by the team of Sahara Enviro ensures low temperature, low pressure & safe operations that optimise commercial viability and sustainability.

Uncondensed gases are repurposed for internal heating or power generation within the facility, contributing to sustainability

The produced fuel can be utilized to power vehicles, buses, or industrial processes, providing an environmentally friendly energy source for heating applications

Contact Sahasra Enviro

Contact Sahasra EnviroSahasra Enviro processes non-recyclable plastics, including soiled films, multi-material, consumer, and industrial packaging waste (excluding PVC).

Our advanced technology ensures efficient handling of diverse plastic waste streams, making them suitable for conversion into valuable resources.

PLASTIC WASTE

PLASTIC WASTE Used for household bottles, chemical containers, toys, pots, and garden furniture

Found in packaging films, bags, bubble wrap, soft bottles, and wire insulation

Used in bottle caps, drinking straws, tarpaulins, and woven socks

Common in plastic cups, egg containers, packing fillers, and yogurt containers